Related story

How SMEs can Leverage Industrial Historians — Without Spending a Fortune.

Yves Bourgeois on , updated

What will your industrial business gain when you start using a data historian? And what makes it so much better than your current SCADA and DCS systems? Discover the five biggest recurring benefits of the data historian, starting from day one.

In a previous article, How SMEs can Leverage Industrial Historians — Without Spending a Fortune, we talked about how data historians were previously only affordable for large companies in capital-intensive sectors. Not anymore, thanks to open technology and the Automation Revolution amongst SMEs.

The obvious question is: what will your business gain using a data historian? When evaluating its value, you should consider that the implementation of a data historian happens in two distinct phases. First, the data historian is introduced as a solution. In this phase, data acquisition, instrumentation, and trending are the focus.

Second, the historian becomes a technology, a data management platform if you will, in which the acquired data itself becomes a source for advanced data analytics, data science and sometimes an updated business model. More about the latter in my colleague’s article about business models.

Both phases bring merit to any industrial company, and have their distinct added values. In this longread, we will focus on the virtues of a data historian by introducing it as a solution.

But first, let us take a step back, and have a look at what you already have: SCADA and DCS systems.

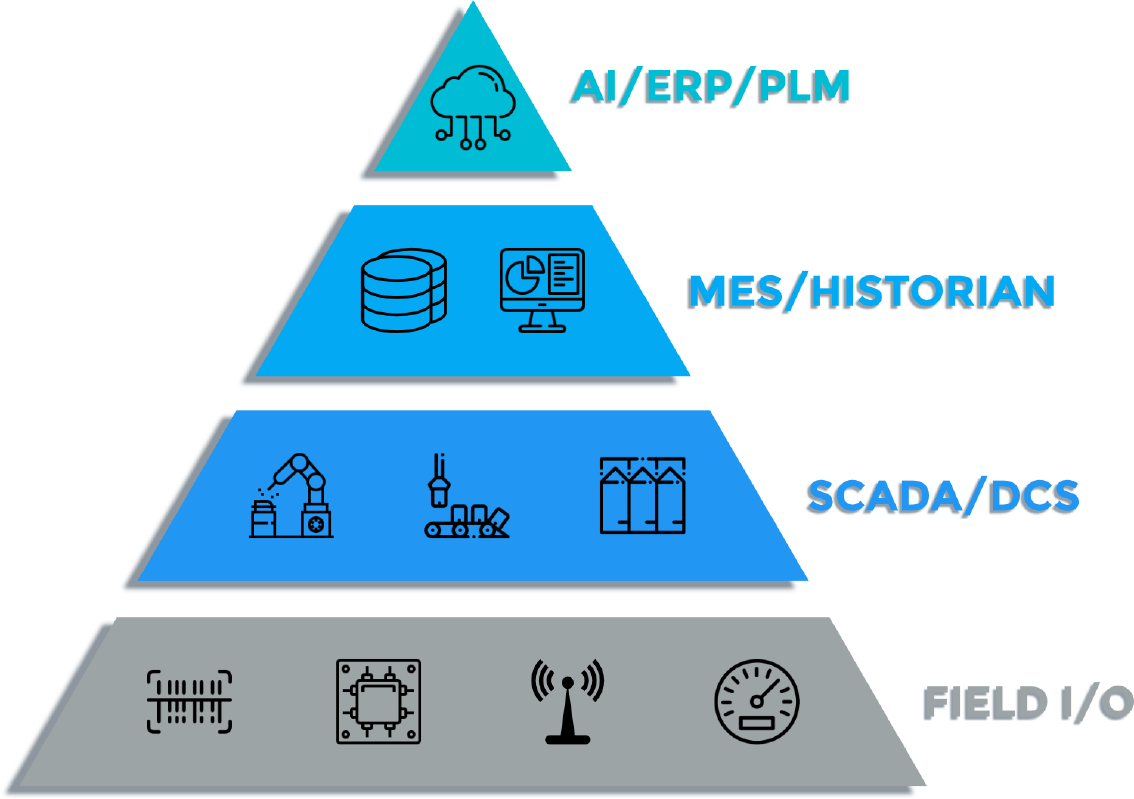

Most companies in process and discrete manufacturing have invested in either SCADA or DCS systems, according to their specific needs. These systems operate on level 0-2 of the automation pyramid. They provide adequate, real-time monitoring of the production process, and guide operators in making decisions in case of alarms or fault-states. Both SCADA and DCS systems even provide a, though limited, ability for trending historical data.

However, both control systems come with severe limitations in regard to data analysis. They only provide a limited amount of historical data, if any, and they are limited to their particular data silo. This means that it is only possible to examine the data for which these systems are responsible, say a single production line, without providing an aggregated overview of the entire plant.

Furthermore, these systems are inescapably locked in their proprietary software model. This makes it very hard, if not impossible, to perform data analysis on the restricted data, in both scope and accessibility, that is contained within them.

Most companies in process and discrete manufacturing have already invested in either SCADA or DCS systems, according to their specific needs. These level 0 - 2 systems provide adequate real-time monitoring of the production process, and guide the operator in making the correct decisions in case of alarms or fault-states during the production process. Both SCADA and DCS systems even provide an, albeit limited, ability for trending of historical data.

The data historian, on the other hand, operates on level 3 of the Industry Automation pyramid. It aggregates the data of the entire plant — over all production lines — and it keeps the data available for as long as needed, if not forever. This opens a new world in terms of data analysis, troubleshooting and process improvement.

Factry Historian frees the collected data. It puts no limitations on integrations with other software and creates the perfect link between Operation Technology and Information Technology. Production savvy people are now able to use the technological infrastructure to analyse production processes in real-time.

Now, let’s have a look at five of the most important benefits a data historian can bring to your business, when introduced as a solution.

Acquired data from sensors (such as temperatures, pressures, etc.) can be linked to contextual data, e.g. the start and end time of an order or a specific batch produced. This will allow you, with the click of a button, to visualize the specific circumstances of the production process, and drill down deep on specific parameters.

This not only saves time for Operations and Quality Managers. It will also keep the focus of said users on the issue at hand. The automatically acquired data gives them the confidence that it is accurate and no data is overlooked. This allows them to make informed decisions based on facts, and not on presumptions.

When quality issues occur, the data historian allows you to thoroughly examine the exact conditions in which a certain batch or order was produced. As such, it is possible to either indicate or exclude whether the production process was the reason for any quality issues. The first will then allow for better training and education of the operators, and to prevent similar quality issues in the future. This will have a direct impact on the yield of production.

Being able to quantify exact problems in the production process also provides a basis for the Continuous Improvement (CI) of said production processes. Different parameters of the process can be measured and fine-tuned to maximize the quality of the product. This has a direct impact on the overall productivity of the plant and reduces costs by avoiding production failures in the future.

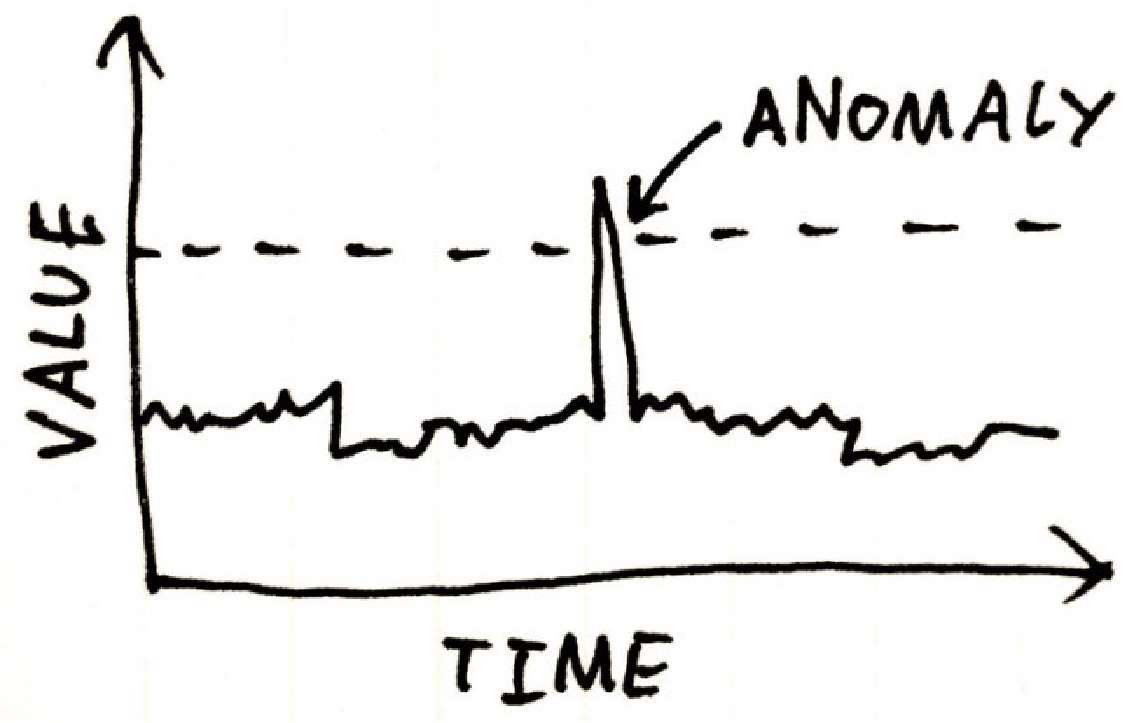

Having all sensory data available, historians are able to detect anomalies during the production process. Anomaly detection can be used to discover e.g. leaks or unexpected temperatures as quickly as possible, reducing the cost of both damage and repairs to a minimum. Anomaly detection can occur either manually, through trending, or automatically through the historian software.

At Factry, we already saw the benefits of anomaly detection at one of our clients: they pinpointed a previously undiscovered leak, which ultimately saved them tens of thousands of euros in unplanned downtime and damages. And this already in the second week our Process Historian was active!

Data historians will not only capture the amount of product that has run through your flow-meter, but it will also show exactly how long your pump has been operating, or how long a generator has been running. Accurate data can be used to schedule predictive maintenance, and send out preemptive warning messages when certain thresholds are bound to be exceeded.

The importance of predictive maintenance has been examined by the World Economic Forum and Accenture. The results are staggering. Using predictive maintenance, the cost of scheduled maintenance is, on average, reduced by 12%, while the total cost of maintenance is reduced by 30%. But most importantly, predictive maintenance eliminated 70% of costly unplanned downtime.

The data historian should not be limited to production data (sensory data such as temperatures, pressures, etc), but can also capture data that is indirectly related to the production process, such as energy consumption. As energy consumption has become one the primary costs in the production industry, having exact data about energy consumption for each part of the production line has become a need by itself, be it in kWh or volume of fuel spent.

The historian provides you with just that: the ability to pinpoint the biggest energy consumers through exact monitoring. It offers you the possibility to use these figures to set up energy-saving projects and directly influence the bottom line of your business.

The data historian provides you with the necessary toolkit to instrumentalise all data that is available in your plant. By doing so, you will be able to use this data to make informed, empirical decisions on a variety of issues, and even use it in CI-projects, be it quality or energy-related. Implementing a data historian in your business will therefore ultimately reflect in an improvement of different facets of the production process, such as cost reduction, yield improvement and minimising unplanned downtime.

Have anything to add to this article? Contact me through yves.bourgeois@factry.io. If you would like a free demo of Factry Historian: contact our sales team and they will be happy to help.